Maintenance Services Provided by Dhaval Engineering

Dhaval Engineering specializes in providing top-notch maintenance services for a wide range of industrial equipment and systems. With our expertise and experience, we offer comprehensive solutions to ensure the smooth operation and longevity of your valuable assets. Our team of skilled technicians is well-versed in various maintenance techniques, including static & rotary Equipments, High Pressure hydro jetting, torquing & tensioning and scaffolding.

StaticStatic Equipment Maintenance

we understand the critical importance of maintaining the integrity and reliability of your equipment. Our technicians are trained to conduct thorough inspections, identify any potential issues, and perform necessary repairs and maintenance tasks to ensure optimal performance and safety. Whether it's pressure vessels, storage tanks, heat exchangers, columns, furnace, HRSG or other static equipment, we have the expertise to keep them operative.

RotaryRotary Equipment Maintenance

Rotary equipment plays a vital role in many industrial processes, and our maintenance services cater to their specific needs. We have expertise in carrying out maintenance of pumps, compressors, steam turbines, motors, extruders, fans. Our team conducts meticulous inspections, performs necessary repairs/overhauling and replacements of worn out parts, and implements preventive maintenance strategies to minimize downtime and maximize efficiency.

Hydro JettingHydro Jetting for Cleaning

Hydro jetting is an effective method for cleaning various process equipments, and we offer specialized services in descalling area. Using high-pressure water jets, we can remove stubborn debris, grease, and other obstructions from pipelines and tubes.We have more than 15 numbers of high pressure hydrojetting machines equipped with automated tube lancer.

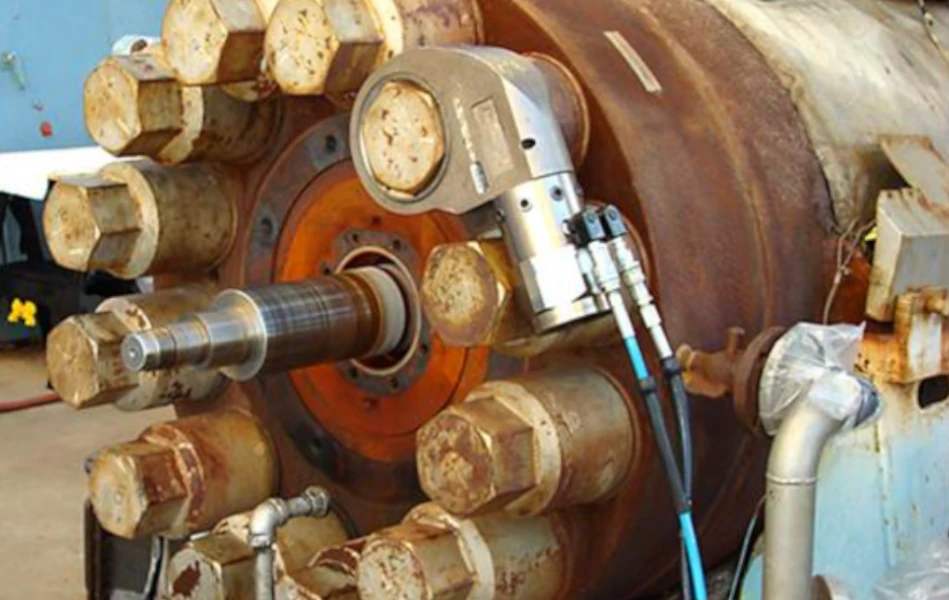

Torquing & TensioningTorquing & Tensioning procedures

Torquing & tensioning are critical procedures in maintaining the structural integrity and safety of various equipment, such as pipelines, flanges, and valves. Our skilled technicians are trained in the proper application of torque and tension to ensure optimal performance and prevent leaks or failures. With our meticulous approach and state-of-the-art tools, we guarantee accurate and reliable torquing & tensioning services.

Heat ExchangerHeat Exchanger Cleaning

Heat exchangers are vital components in many industrial processes, and their efficient operation is crucial for optimal productivity. Our company specializes in heat exchanger maintenance, offering comprehensive cleaning, inspection, and repair services. Our skilled technicians are well-versed in handling shell & tube type, plate type, fin type heat exchangers, ensuring they are free from fouling, corrosion, and other issues that can impact their performance.

Scaffolding Services

In addition to equipment maintenance, we provide scaffolding services to ensure the safety and accessibility of work environments. Our team is trained in erecting, inspecting, and dismantling scaffolding structures, enabling efficient and secure maintenance operations at various heights. We prioritize safety and compliance with regulations, allowing you to focus on your core operations with peace of mind.We have successfully completed scaffolding of stacks/chimneys and have in-house material to erect 25000 m3 scaffolding

Process Column

We are specialized in providing a wide range of services related to process columns and reactors, including cleaning/maintenance, Tray replacement/modifications, Tower attachments replacement/modification, Nozzle RF pad replacement, dehumidification. We offer comprehensive solutions to meet the specific needs of our clients.

Catalyst Loading

Catalyst loading is a critical aspect of process columns and reactors, as catalysts play a vital role in many chemical reactions. Our skilled technicians are trained in the precise and efficient loading of catalysts into reactors, ensuring optimal distribution and performance. We follow strict protocols and safety guidelines to maintain the integrity of the catalysts and maximize process efficiency and product quality.